How Much is a Laser Cutting Machine?

If you’re a business owner who is looking for a way to cut through materials like sheet metal, stainless steel, plastic, and wood quickly and easily, you may be wondering how much a laser cutting machine costs. In this blog post, we’ll provide you with an overview of the cost of various laser cutting machines so you can choose the one that best meets your needs.

You’ve decided that you need a laser cutting machine for your business, but you’re not sure how much they cost or which one is right for you.

Laser cutting machines come in all shapes and sizes, and the price can vary depending on the design and ability of the machine. You should also expect to pay a higher price for fiber lasers, which are known for their energy efficiency and accuracy.

Do your research before making a purchase. Read reviews and compare prices to find the best laser cutting machine for your needs.

The different types of laser cutting machines

When it comes to laser cutting machines, there are three main types of lasers: CO2 lasers, fiber lasers, and ultraviolet (UV) lasers.

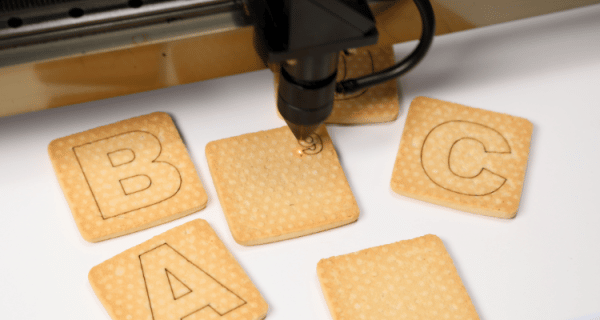

CO2 lasers are the most common type of laser cutting machine. They’re versatile and can be used on a variety of materials, including metals, plastics, glass, and composites. CO2 laser engravers are available in both desktop and industrial models. The Glowforge is one of the most popular brands.

Fiber lasers are the most energy-efficient type of laser cutting machine. They’re also more accurate than CO2 lasers and can cut through thicker materials. Fiber lasers are typically used for cutting metal, but they can also be used on plastics and composites.

UV lasers are the newest type of laser cutting machine. They’re more expensive than CO2 and fiber lasers, but they offer the highest level of precision. UV lasers can be used on a variety of materials, including metals, plastics, glass, and composites.

You can also find fiber laser machines for engraving projects. If you are looking for a laser engraving machine, you’ll want to do your research on the best laser engravers and find the one that suits your needs and budget. These work well for thinner materials such as mild steel, plastic, and sheet metal.

How much does a laser cutting machine cost?

The price of a laser cutting machine can vary depending on the type, size, and ability of the machine. You can find an affordable laser cutter, or if you want something more heavy-duty, you can find a metal laser cutter with additional features. It’s completely up to you and your specific needs, and the price of a laser cutter depends on the features you want and the laser power. You can even find a high-quality used machine if you want to cut down on the price point.

CO2 lasers start at around $3,000 for a small, desktop model and can go up to $500,000 for an industrial-grade machine. We personally have a Glowforge Pro, which we love. It costs $6,995, though the basic is on the lower end at $3,995. You can check our full Glowforge comparison here.

Fiber lasers start at around $10,000 and can go up to $1 million for an industrial-grade machine, though the average cost is between $20,000 and $40,000.

The price range for UV lasers starts around $50,000 and can go up to $1 million for an industrial-grade machine. The total cost you pay will depend on your specific needs, but an entry-level laser should suffice for a wide range of materials. You should be able to find a metal fiber laser at an affordable price. If not, you can always find someone who offers laser cutting services if you only need it for one or two DIY projects.

CLICK HERE TO SAVE UP TO $500 ON A GLOWFORGE MACHINE

How a laser cutter works

Laser cutters work by directing a high-powered laser beam at the material that you want to cut. The laser beam is generated by a laser source, which is typically a gas (such as carbon dioxide) or a solid-state (such as a fiber laser), resulting in precise cuts.

The laser beam is then reflected and focused through a lens onto the material. The material is heated by the laser beam and melts, vaporizes, or burns away.

There are different types of lasers that cut through different materials, so the type of laser cutting machine you need will depend on the material you want to cut and the thickness of the material. For example, if you want to cut metal, you’ll need a fiber laser. If you want to cut wood or plastic, you can use a CO2 laser. The different features can help you determine what you need.

The benefits of using a laser cutter

Laser cutters are fast, accurate, and easy to use. They can cut through a variety of materials, including metals, plastics, glass, and composites. Laser cutters are also more energy-efficient than traditional cutting methods.

If you’re looking for a fast, accurate, and easy-to-use way to cut through materials like metal, plastic, and wood, a laser cutter is a great option. Laser cutters are available in a variety of sizes and price ranges to fit your needs.

What you can use a laser cutter for

Laser cutters can be used for a variety of applications, including:

- Cutting metal for industrial applications

- Cutting wood for furniture or cabinetry

- Cutting plastic for prototypes or models

- Cutting glass for stained glass or mosaics

- Cutting wood for fun projects

- Cutting acrylic

Factors to consider when purchasing a laser cutter

When purchasing a laser cutter, there are a few factors that you should keep in mind, including:

- The type of machine that you need (CO2, fiber, or UV)

- The size of the machine

- The power of the laser

- The precision of the machine

- The price of laser and how much you are willing to spend

- Your specific needs and budget

Once you’ve considered all of these factors, you’ll be able to choose the best laser cutter for your needs.

The cost of owning and operating a laser cutter

In addition to the initial cost of purchasing a laser cutter, there are also ongoing costs that you’ll need to consider, such as:

- The cost of the laser source

- The cost of the lens

- The cost of power

- The cost of maintenance

- The cost of materials

When budgeting for a laser cutter, be sure to factor in all of these costs so that you can make an informed decision.

How to use a laser cutter and what are the best practices for getting the most out of this equipment.

Laser cutters are easy to use and can be a great addition to your business. Here are a few tips for getting the most out of your laser cutter:

1. Choose the right machine for your needs.

2. Make sure you have the proper safety equipment.

3. Follow the manufacturer’s instructions.

4. Be aware of the cost of ownership and operation.

5. Use the machine for its intended purpose.

By following these tips, you’ll be able to get the most out of your laser cutter and maximize its potential.

Laser cutters are available in a variety of sizes and price ranges to fit your needs. The cost of owning and operating a laser cutter can be an important investment for your business, so it’s important to do your research before making a purchase. By following these tips, you’ll be able to get the most out of your laser cutter and maximize